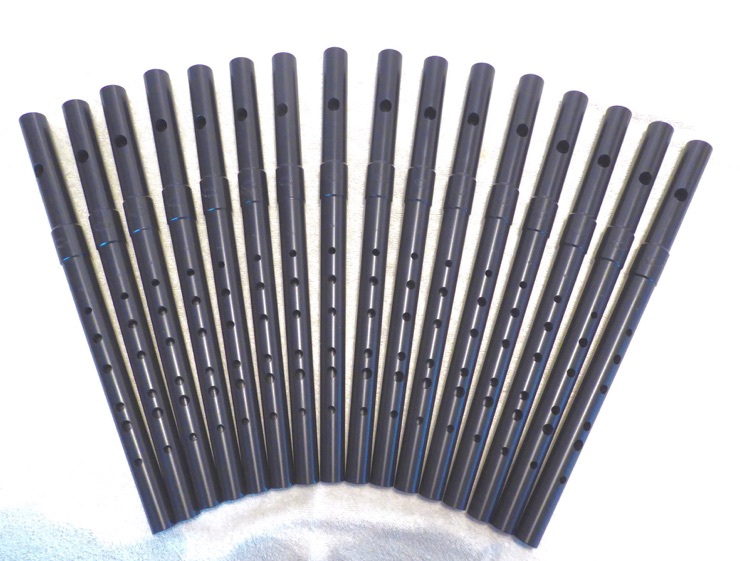

Band Fifes

I've been making fifes and smaller flutes for many years, using the standard materials that I use for all my flutes, mainly African blackwood and silver, for mounts.

From the makers point of view one of the major considerations with smaller flutes is that, of course, they are expected to be less expensive than their larger brethren. A little consideration of the practicalities though, shows that, although production costs are reduced by smaller quantities of materials, and less time spent in manufacture due to generally fewer joints and therefore tenons and sockets, other factors almost cancel this out.

Materials, expensive as they are, make only a very small contribution to the final cost, and despite size, almost all the processes involved in larger flutes are also involved with fifes.

Each piece must be drilled,reamed, turned, tuning slides inserted, finger holes drilled, embouchures cut, and all the final finishing, undercutting and cosmetic finishing of surfaces undertaken. In many cases these processes are made more difficult by the fact that the maker is essentially working in miniature. So although the smaller flutes are less expensive (see price list ) they're probably not as expensive as they should be.

You might wonder where all this is leading, but the point I'm trying to make is that for those involved in fife bands, prices of wooden instruments can be prohibitive.

So my New Model Band Fife is made from Ertacetal plastic, probably better known as Delrin.

This material has many advantages from the player's point of view.

It's just about indestructible, and requires almost no maintenance, and from the makers point of view, is a cheaper material, which because of it's homogenous nature, doesn't need the support rings that timber does, again reducing costs.

There are certain aspects of Delrin as a material that make things more difficult for the maker, but these are technical challenges concerning working in plastic, which require a more consistent approach, and are not unsurmountable.

The photo above are the fifes I made for the band, which are in B at a = 442 by special order.

Also available at a = 440 and in Bb.

Below are a few more pics.

First, the whole thing dis-assembled. This is actually the prototype, where I made the joint as a sliding fit/basic tuning slide, without lapping of any kind. A normal cork joint can also be provided

And a couple of close ups of the head and embouchure...

Elongated oval embouchure. Edge here is

highlighted for photographic purposes